Laser marking machine marking PVC material

Laser marking machine marking PVC material

PVC material is a kind of non-crystalline vinyl polymer. This kind of material has good resistance to oxidants, reducing agents and strong acids. At present, many occasions use products made of PVC materials, electrical enclosures, sewer pipes, industrial accessories and so on. For such a widely used product, we often need to mark the product LOGO, model, etc. on its surface. Common marking methods are: traditional ink coding and laser marking. What are the advantages of laser marking machine processing on the surface of PVC material?

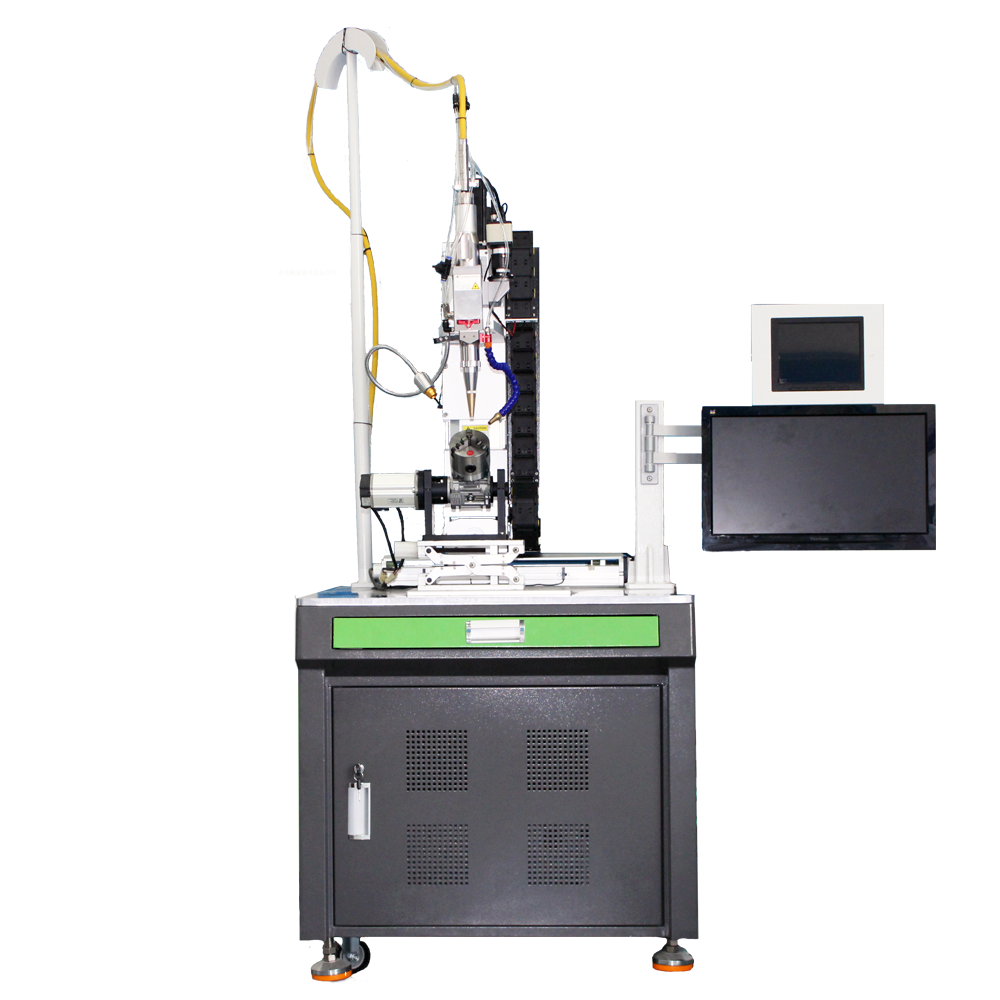

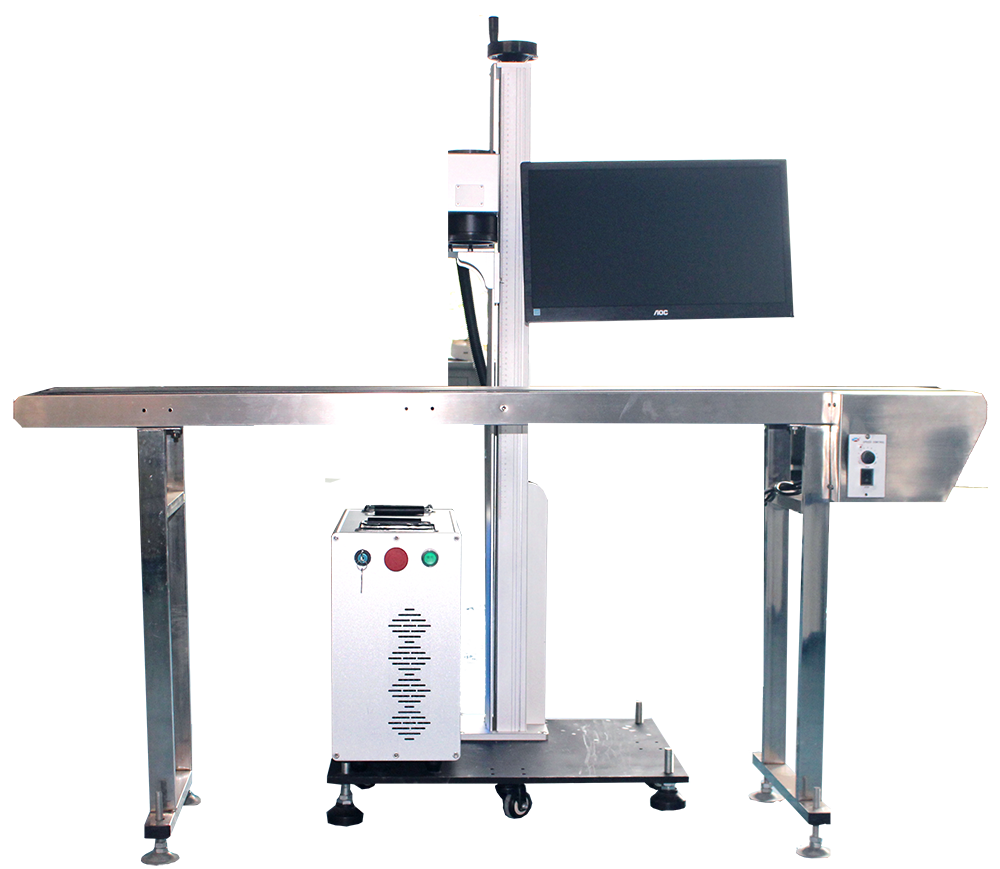

Generally speaking, near-infrared laser or far-infrared laser (such as CO2 laser) is currently used for marking on PVC materials. Carbon dioxide laser marking machines are commonly used for far-infrared laser marking machines. The wavelength of this laser is It is 10.6 μm. This type of marking machine can make yellow and red handwriting on PVC materials. Because the function of carbon dioxide laser can be very large, such as the current universal 30W power marking machine and 50W power marking machine, so This type of laser marking machine can mark at a very high speed, which is very suitable for processing on the assembly line, replacing those less environmentally friendly ink coding.

The laser marking machine is used as the processing means. There is no processing force between the workpiece and the workpiece. It has the advantages of no contact, no cutting force, and low influence on the workpiece, ensuring the original accuracy of the workpiece. The laser marking machine has good space control and time control. It has a large degree of freedom in the material quality, shape, size and processing environment of the processing object, and is particularly suitable for automated processing and special surface processing. . The marking is fine, the lines can reach millimeters to micrometers. Marking and modification using laser marking technology is very difficult. It is extremely important for product anti-counterfeiting and is very popular in the PVC processing industry.