How to test and adjust the focal length of laser marking machine

How to test and adjust the focal length of laser marking machine

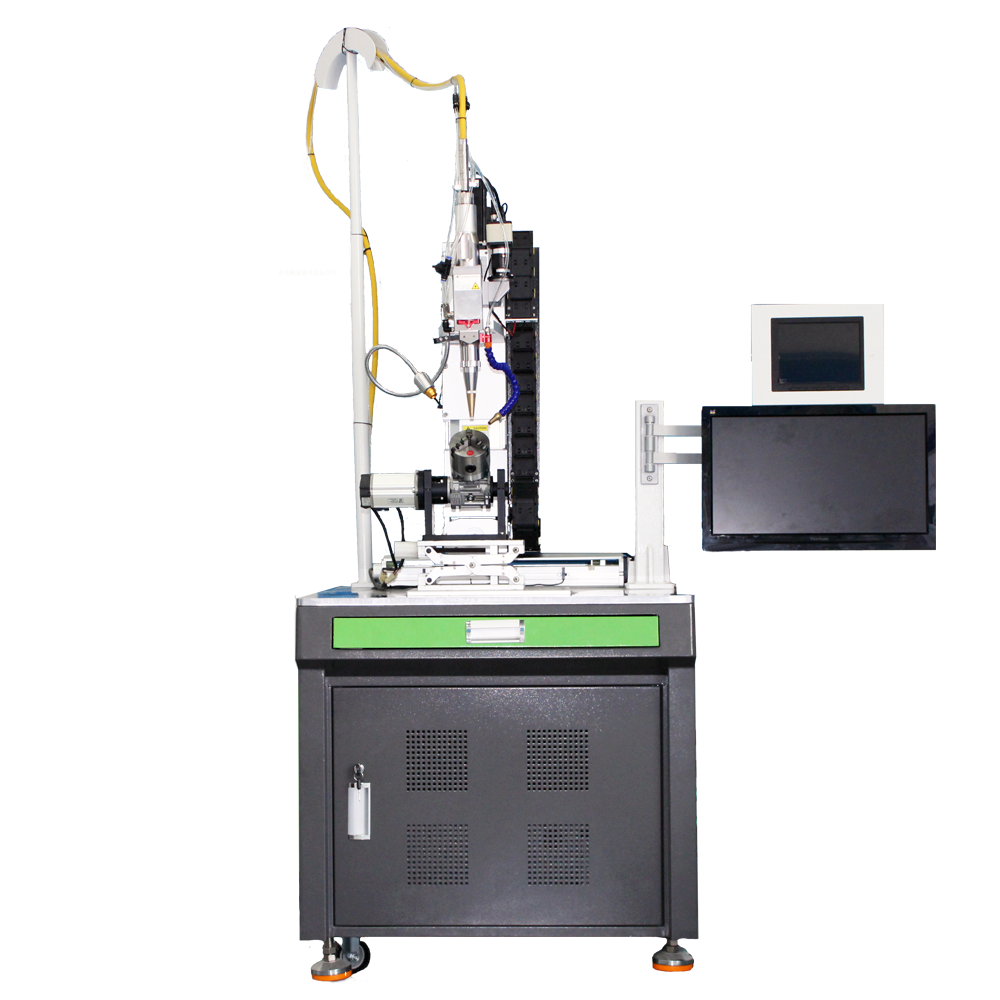

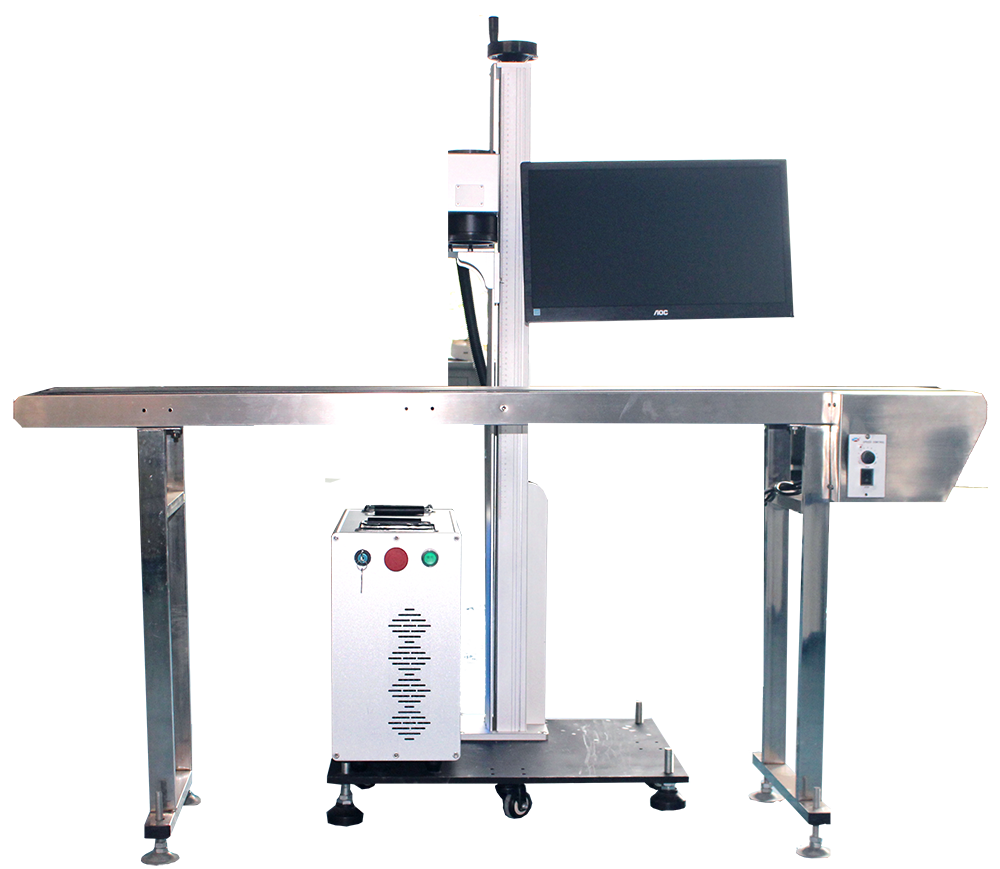

In general, when laser marking machine manufacturers install laser equipment for buyers and train and adjust samples, the importance of focal length is emphasized. Focal length, also known as focal length, is a measurement method for measuring the concentration or divergence of light in optical systems. Refers to the distance from the center of the lens to the focal point of light gathering. So how to adjust the focal length? Here are a few methods:

1. First draw a square or circle of about one centimeter on the marking software. After conventional filling, adjust the laser energy to a relatively large value in the laser setting parameter column, use the low frequency as far as possible, and then check continuous marking. On the surface, a block such as a metal business card is placed at the projection position of the surface, and the light is continuously marked. The Y axis is moved up and down until the laser is applied to the metal business card with the energy of the strong, the sound is crisp, and the color is bright. Test up and down several times to find the right focal length.

2. After the equipment manufacturer notifies the current equipment focal length data, it can be recorded, and then after each product switch. You can point the end of the ruler directly on the product surface. The scale value refers to a reference surface on the field lens, which shakes up and down to scale the data. This method is suitable for all laser marking machines, but the disadvantage is that if the position of the laser engraved product is concave or the steel rule is not suitable, this method is not practical.

3. In general, the work surface is fixed. You can also set the focal length according to the program in the computer to make the laser process normally. At this time, the focal length of the object needs to be determined according to the area of the object and laser focusing. If there is no way to adjust the worktable, it is necessary to change the focal length according to the thickness and hardness of the material and adjust it to a suitable processing focal length.

The adjustment of the focal length of the laser marking machine requires the operator to strictly follow the correct method, so as to prevent the machine from being worn out due to improper operation, so that processing cannot be performed normally. Before processing, the customer should analyze and adjust the material to ensure that the setting of the focal length of the laser marking machine is accurately adjusted.