Advantages of laser marking machine development in many processing industries

Advantages of laser marking machine development in many processing industries

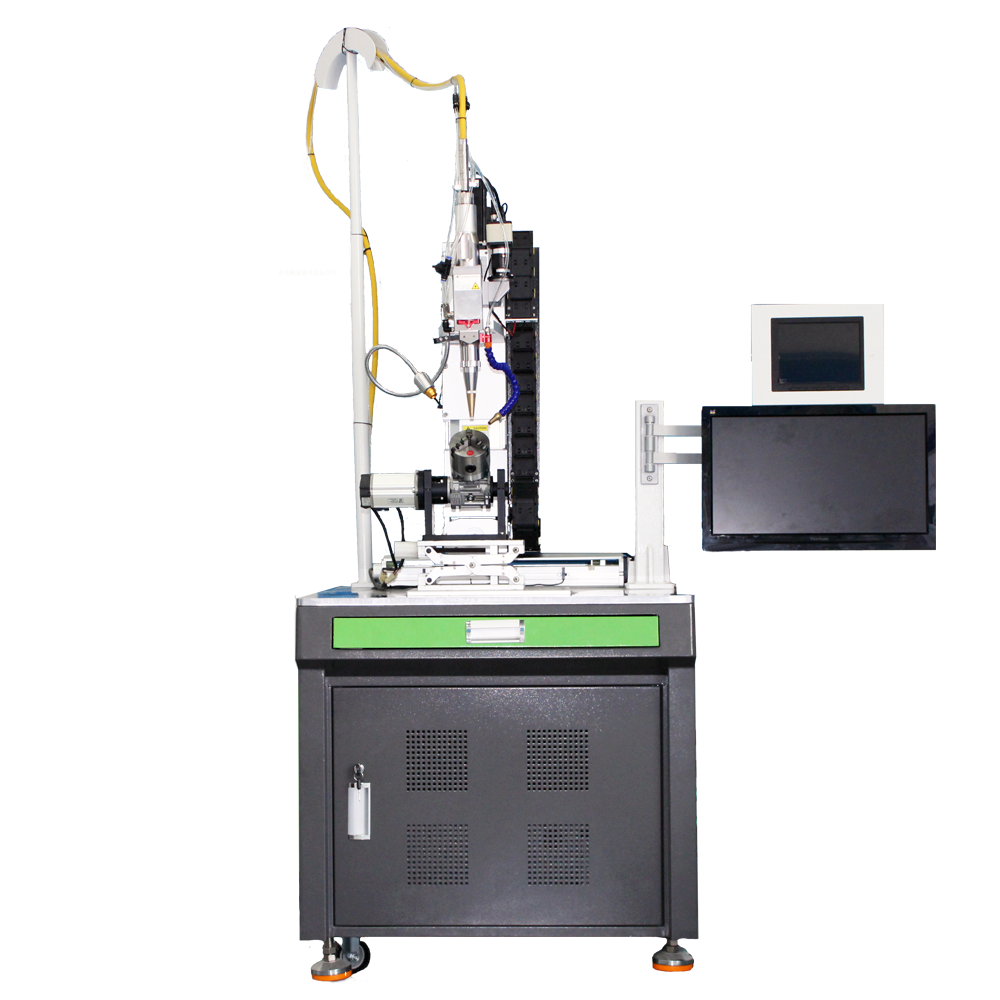

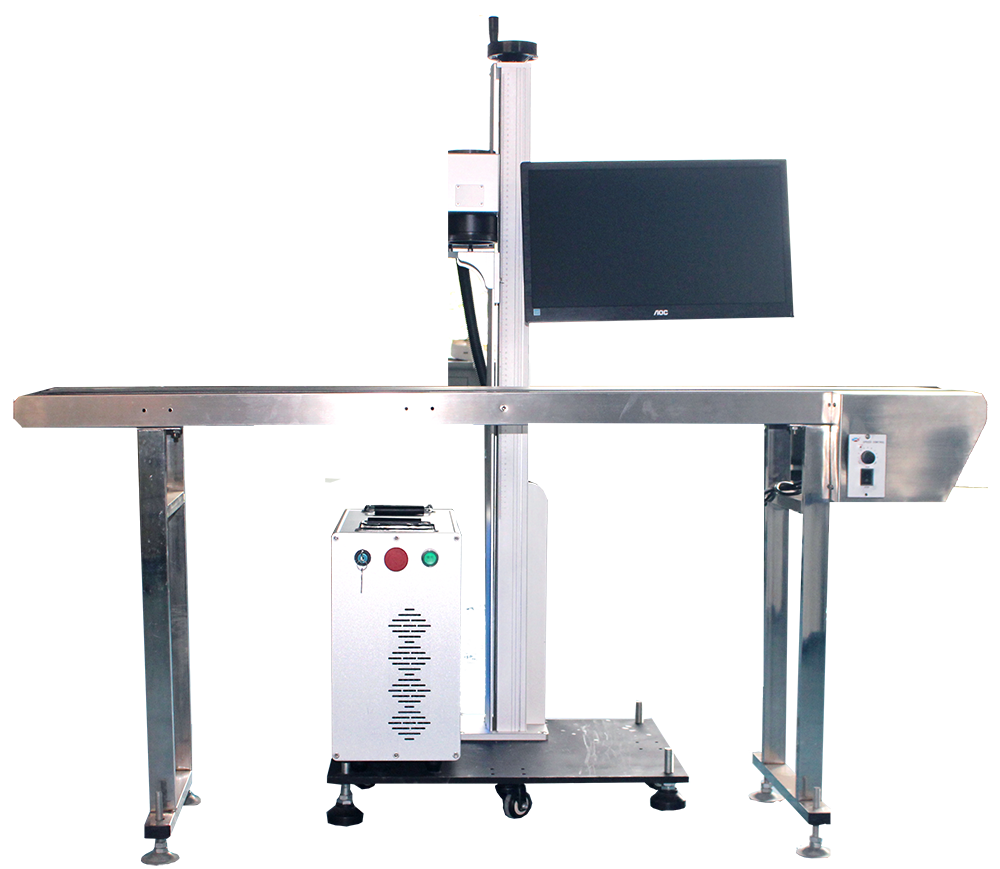

Laser marking machine is a kind of processing equipment that uses laser beam to act on the surface of the workpiece material. Its huge advantages have made laser marking machine develop rapidly in many industries. More and more production and processing manufacturers choose to buy Use, then what are the advantages of laser marking machine that can gradually replace some traditional processing methods to get popular praise?

1. A very thin laser beam of a laser marking machine is like a tool for removing material on the surface of an object point by point. One of the advanced features is that the marking process is non-contact processing, there is no mechanical squeeze or mechanical stress, so it will not damage the workpiece, ensure the integrity of the product, and reduce the waste of the workpiece.

2. The laser's space controllability and time control are very good. The material, shape, size and processing environment of the object can basically be adapted, and the 360-degree flexible marking is especially suitable for automatic processing and special surface treatment. It can be integrated with other equipment on the production line to improve the automation of the production line.

3. Laser processing has no pollution source, and it is a clean and pollution-free high-environment processing technology. Environmental protection monitoring is an important indicator in current manufacturing. Many products using silk screen printing or ink coding cannot meet environmental protection requirements, but laser marking machines will not cause contamination of consumables.

4. The laser marking machine has a wide application range for materials. It can mark metals, plastics, ceramics, glass, paper, leather and other materials of different types or different hardnesses. It also has many applications in the electronics industry, automobile manufacturing, mobile phone manufacturing and processing industries, and bathroom appliances. .

5. The laser marking machine has another important advantage, that is, the stability of the equipment is strong, the marking effect is very good, the lines are delicate, the marking is clear, the durability is good, it will not fade, and it can meet the effects of many processors. Requirements, and can also carry out special marking processes such as peeling paint, hollowing out, cutting and punching.

Laser marking machine greatly improves the processing efficiency, saves a lot of labor costs for production and processing manufacturers, guarantees the marking quality, improves the processing speed, advances with the times, and speeds up the process of production automation.